I’ve been working in the construction industry since 1988, starting in the UK and over the years expanding to many other countries. Through all that experience, I’ve seen countless building methods and approaches, but today I can’t think of a better construction method for houses than panelised construction. Here’s why.

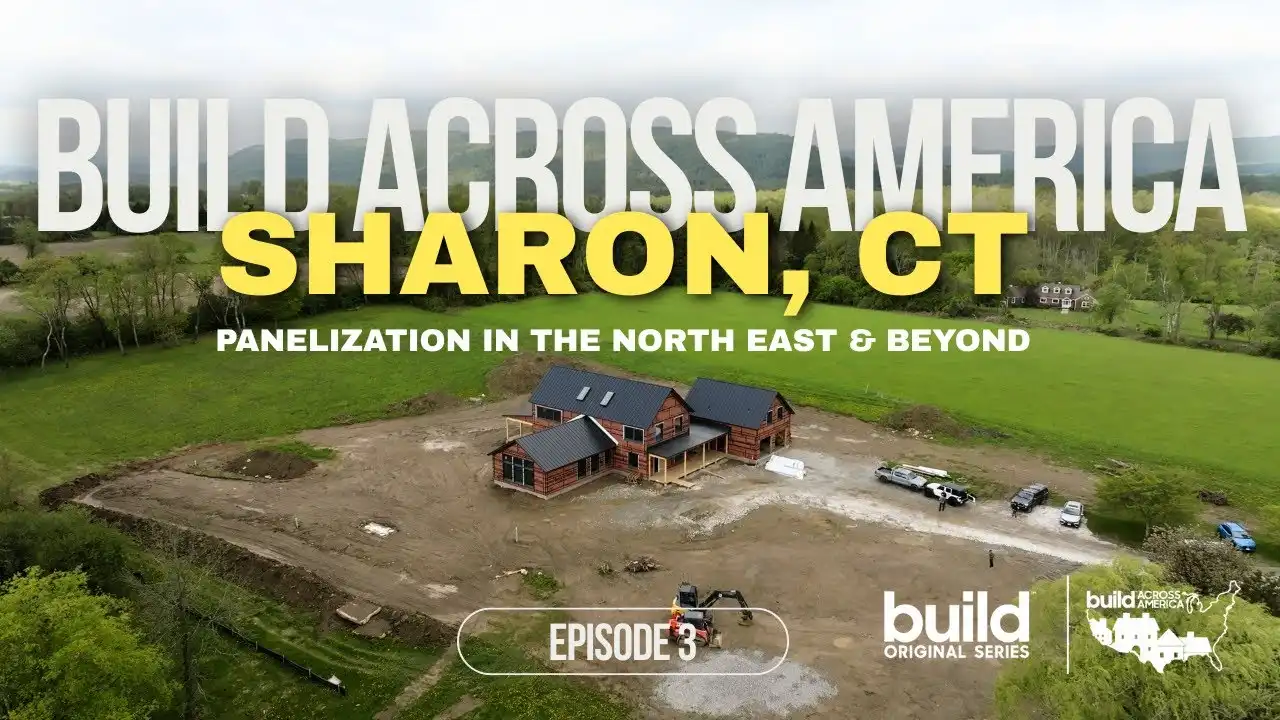

Matt Risinger, our ever-present guest author on The Build Review, recently toured Bensonwood’s factory in New Hampshire, USA, and visited one of their project sites. His discoveries perfectly illustrate everything I’ve come to believe about the benefits of panelised (prefabricated) construction for building homes.

If you’re considering building a new home and want something that’s genuinely built to last centuries – which unfortunately can’t be said for many new homes today – whilst delivering exceptional performance and surprising cost savings, then panelised construction might be exactly what you’re looking for.

Key Benefits That Make All the Difference

Controlled Environment Manufacturing: Everything is built in climate-controlled factories, eliminating weather delays, reducing waste, increasing productivity and efficiency, and creating safer work environments

Superior Material Performance: The clean, controlled conditions allow critical components like flashing and tapes to bond properly – something that’s nearly impossible to achieve consistently on wet, dusty, or cold building sites

Unmatched Quality Control: Every component is built in perfect conditions, free from the compromises that plague traditional site construction

Exceptional Performance: Achieving airtightness levels and thermal performance that traditional construction simply can’t match consistently

Future-Proof Design: Built to last generations with easily accessible systems for future upgrades

Speed Without Compromise: From foundation to watertight in weeks, not months, without sacrificing quality

Precision Manufacturing: CNC machinery and factory processes eliminate human error and material waste

What Exactly Is Panelised Construction?

Think of it like this: instead of your builder turning up to site with a pile of timber and spending weeks framing your house in whatever weather Mother Nature throws at them, entire wall sections, roof panels, and floor assemblies arrive on trucks, pre-built in a climate-controlled factory. We’re talking about complete wall systems that are already insulated, have windows fitted, electrical conduits installed, and are fully airtight before they even leave the factory.

When Matt watched these components being built at Bensonwood, he was genuinely impressed. They’re using advanced CNC machinery that cuts every piece of timber to precise measurements, pre-drills holes for fixings, and even marks exactly where each component goes. There’s no guesswork, no “that’ll do” attitudes, and certainly no getting soaked whilst trying to frame a roof in a downpour.

The Quality Advantage You Simply Can’t Get On-Site

Here’s something that even the most seasoned builder resonates with, every single joint, every piece of tape, every insulation detail is completed in perfect conditions. The factory maintains a steady 20°C temperature year-round, there’s no wind, no rain, and no pressure to rush because of weather.

The precision is remarkable. Matt watched them install triple-glazed windows with proper flashing details that would make a building scientist weep with joy. They’re using specialised tapes from Ireland, creating continuous air and vapour barriers, and ensuring every penetration for electrical, or plumbing is perfectly sealed. Try achieving that level of detail on a wet Monday morning in winter on a traditional muddy building site!

The quality control is built into the process too. Each panel has QR codes tracking its progress through different stations, and they’re doing factory blower door tests on components before they leave. By the time these panels reach site, they’re already achieving airtightness levels that most traditionally-built homes can only dream of.

Performance That Actually Delivers on Promises

Let’s talk numbers because what Matt found is genuinely impressive. The house he visited in Connecticut achieved an airtightness of 0.41 ACH50 – that’s below Passivhaus standard. The walls were delivering R35 (that’s about 6.1 m²K/W for those using metric), and the roof was hitting R51 (nearly 9 m²K/W). These aren’t theoretical performance figures; this is what they’re actually achieving in real homes.

But here’s what really matters for you as a homeowner: those performance levels translate into dramatically lower energy bills and incredible comfort. No cold spots, no draughts, and heating systems so small they’re barely noticeable. The mechanical room in the house Matt toured was compact enough to fit under the stairs.

When Does Panelised Construction Make Sense?

If you’re building in a challenging climate: Whether you’re dealing with harsh winters, scorching summers, or simply unpredictable weather, factory-built components aren’t commonly affected by site conditions during construction.

If quality matters more than initial cost: Yes, panelised construction can cost more upfront (location dependent), but you’re generally getting precision that’s simply incredibly difficult to achieve with traditional stick frame building methods. Plus, the long-term savings in energy costs often offset the initial investment. Maintenance cost and time should be lower too over the life of the building.

If you want speed without compromising quality: The house Matt visited went from foundation to watertight in just three weeks with less resources on site. That’s not rushing; that’s efficiency. Getting weather-tight quickly means trades can start interior work quicker, and there’s less risk of moisture-related problems.

If you’re building remotely: Panelised construction can work brilliantly for rural or difficult-to-access sites. The manufacturer often sends experienced crew members to guide local builders through the assembly process.

The Future-Proofing Advantage

Here’s something that particularly impressed me about Bensonwood’s approach: they design what they call “the core building” to last 200-300 years, whilst keeping all the systems and finishes easily accessible for future upgrades. The structural envelope is built to outlast generations, but if your great-grandchildren want to rewire the house or upgrade the plumbing, they can do so without touching that high-performance shell.

This isn’t just about building a house; it’s about creating what they call “liveable structure” that can adapt to changing needs over centuries.

Is It Right for Everyone?

Honestly? No. If you’re building a basic spec home on the tightest possible budget, not necessarily caring about the materials and products you’re using, then traditional stick framed construction might be more appropriate. There’s also one practical consideration: your site needs to accommodate a crane or have space for telehandlers, because these panels are big and heavy – we’re talking about complete wall sections that can weigh several tonnes.

But if you’re serious about performance, longevity, and creating a home that will genuinely stand the test of time, panelised construction deserves serious consideration.

The technology has matured enormously over the past 50 years, and manufacturers like Bensonwood are shipping components across entire continents successfully. The precision, performance, and long-term thinking involved in this approach represents what I believe is the future of quality home construction.

Unfortunately, many countries still don’t use panelised construction, have the manufacturing capability, or know-how. It doesn’t mean that you can’t import panelised assemblies from overseas, but your building code and councils are unlikely to be skilled or knowledgeable to make your building consent acquisition a painless exercise. But where there’s a will, there’s a way.

If you’re planning a new build and want something exceptional, start researching panelised manufacturers in your area. The investment in quality at this level pays dividends for generations.

Learn More About Panelised Construction

To see exactly how panelised construction works in practice, I highly recommend watching Matt Risinger’s detailed factory tour and site visit. His video provides an in-depth look at the manufacturing process, the precision involved, and the real-world performance results that make panelised construction such a compelling choice for quality-focused homeowners.

Contributor

Related

Showcasing a Panelised Mass Timber Student Dorm Build that Uses Robots

How Can Housing Departments and Developers Learn from Local Failures?